What is PUF panel?

PUF panels are composed of a thick layer of rigid PUF sandwich between two protective facings, generally metal sheet are used a facings. PUF panels are a type of insulated panel made from polyurethane foam (PUF).

Experience the strength and power of Pronto PUF panels, the perfect choice for your construction project. Our panels are composed of a thick layer of rigid PUF sandwiched between two protective facings, such as metal, cement, metal in wood finish, and veneer, providing superior structural strength and excellent thermal insulation. Pronto PUF panels will reduce energy costs and improve building performance, so you can trust in the dependable results of our panels. Experience the power and trust of Pronto PUF panels for a construction project that’s built to last.

What is life of PUF panel?

The life of a PUF panel depends on the type of panel and the environment in which it is used. Generally, PUF panels have a life expectancy of up to 25-40 years, depending on the type of panel and the environment in which it is used. For example, PUF panels used in industrial applications may have a shorter life expectancy than those used in residential applications. Additionally, PUF panels exposed to extreme temperatures, humidity, or other environmental conditions may have a shorter life expectancy than those used in more moderate climates. Second most important factor determining age of PUF panels is the quality and brand. Panels manufactured by a reputed brand like Pronto in India have longer life span, when compared to product made by local processers.

How long does puf panel roof last?

Puf panel roofs typically last about 25 years, depending on the type of panel and the climate in which they are installed. In India, Pronto panels have developed indigenous technology to adapt with Indian conditions, uses, budget and mindsets. Pronto panels are best suited for Indian customer. Pronto panels have the highest life expectancy of Roof in Indian conditions.

What is the strength of puf panel? Is PUF panel strong?

Puf panels are made of polyurethane foam, which is a strong and lightweight material. The foam has a high compressive strength of up to 250 kPa, making it an ideal material for insulation and structural applications. It also has a high thermal resistance, making it an effective insulator. Additionally, the foam is resistant to water, fire, and other environmental factors, making it a durable and reliable material for construction.

Pronto’s Polyurethane foam (PUF) panels are renowned for their durability and load-bearing capabilities over long spans, making them an ideal material for the construction of large cold storages and mushroom chambers. The panels are also lightweight, allowing for easy installation with minimal support. A dummies explanation can be, For example, a chamber roof span of 30 feet only requires two panels, each measuring 15 feet in length, with support only needed at joint locations. Furthermore, the panels are lightweight and can easily support the weight of six adults standing over a 6’ span without bending. This makes installation easy, with minimal support needed only at joint locations. Companies such as Pronto have developed the technology to make PUF panels suitable for Indian conditions.

How durable is a puf panel house?

Puf panel houses are highly durable and can last for decades. Pronto, a company in India, has been manufacturing puf panel houses since the early 2000s. PUF panels are made from high-grade polyurethane foam and are designed to withstand extreme weather conditions. The panels are also fire-resistant and can withstand temperatures up to 250°C. Additionally, the panels are insulated to keep the interior temperature comfortable and reduce energy costs.

India’s most contemporary construction using these panels is located in Princely city of Jaipur. The ultra-modern farm house is named as Pronto House. Pronto has constructed a large and beautiful looking building using their puf panels, which is a testament to their durability. Do watch their construction video for more details.

Is puf panel heat resistant? Is PU foam heat resistant?

Yes, PUF panel heat resistance is a key feature of this type of insulation. PUF panels are made from polyurethane foam, which has a high thermal resistance and can withstand temperatures up to 200°C. This makes PUF panels an ideal choice for applications where heat resistance is a priority. Additionally, PUF panels are also resistant to water, fire, and other environmental factors, making them a great choice for a variety of applications. All modern day cold storages and temperature sensitive buildings are made from PUF panels due to their extremely high temperature resistance properties. A building made using PUF panels from reputed brands like PRONTO make a huge savings in air-conditioning cost. Certain buildings like call centers have a payback period of less than 5 years just from savings in cost of air-conditioning.

Is puf panel waterproof? Does PUF absorb water?

The water absorption of PUF panels is very low, typically less than 0.2%. This means that the panels are highly resistant to water and moisture, making them an ideal choice for areas that are exposed to the elements. Additionally, the steel layers provide additional protection against corrosion and other damage. The water vapor permeability is generally between 0.05 and 0.2 ng/Pa.s.m2.

In Brands like Pronto, the water absorption of PUF panels is very low due to its closed cell structure. The closed cell percentage of PUF panels is typically between 95-98%, which means that only 2-5% of the panel is open to water absorption. This makes PUF panels highly resistant to water and moisture, making them an ideal choice for areas that are exposed to the elements.

Is PUF fire resistant? Is PUF fire resistant?

Yes, PUF (Polyurethane Foam) is fire resistant. It is a closed-cell foam that is made up of a combination of polyols and isocyanates. It has a high thermal insulation value and is able to withstand temperatures up to 250°C (482°F). It is also self-extinguishing and does not support combustion.

What is the fire rating of PUF? Is puf panel heat resistant? What is the fire rating of PUF?

PUF is available in markets with various fire ratings. Small processors make PUF having lower fire ratings due to their low raw material cost. Always buy PUF from reputed manufactures to ensure that you get good fire ratings. A B2 grade self extinguishing rating is minimum you should ask for.

The fire rating of PUF (Polyurethane Foam) depends on the type of foam used and the thickness of the foam. Generally, PUF has a B2 Self-extinguishing fire rating,. However, some types of PUF may have a lower fire rating depending on the type of foam used and the thickness of the foam. For more detailed technical data, please refer to the manufacturer’s product specifications.

What is the thickness of PUF panel? What is PUF thickness? What is panel thickness?

Typically 30mm to 200mm thickness.

What is the thermal conductivity of PUF panels?

The thermal conductivity of PUF panels depends on the type of foam used. Generally, the thermal conductivity of PUF panels ranges from 0.022 to 0.038 W/mK. However, some types of PUF panels can have a thermal conductivity as low as 0.015 W/mK. The final thermal insulation achieved depends on quality of PUF and its thickness. The thermal conductivity of PUF insulation is typically 0.023 W/mK (at 10°C mean temperature).

What are the application of puf panels? Where are PUF panels used? Why are PUF panels used?

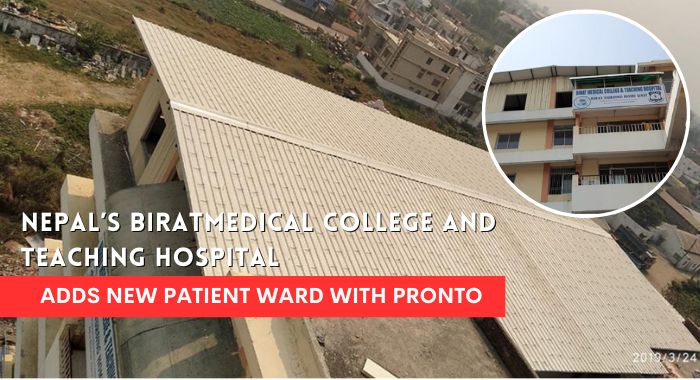

PUF panels are widely used in the construction of farm houses, industrial sheds, animal shelters, cabins, and rooms. They are also used in the construction of cold storage rooms, warehouses, and prefabricated structures. PUF panels are also used in the insulation of roofs, walls, and floors. They are also used in the construction of prefabricated buildings, such as portable cabins, kiosks, and guard houses. PUF panels are also used in the construction of prefabricated swimming pools, and in the insulation of air conditioning ducts.

What chemicals are used for puf insulation?

The most common chemicals used in spray foam insulation are polyurethane and isocyanate. Polyurethane is a type of chemical that is mixed at very high pressure and then sprayed onto surfaces where it creates chemical reaction and expands to form a foam. Isocyanate is a chemical that helps the polyurethane foam expand and harden.

What is the chemical composition of puf panel?

PUF panels are made from polyurethane foam, which is a type of plastic foam made from a reaction between polyols and diisocyanates. The foam is then sandwiched between two metal sheets, such as aluminum or galvanized steel, to form a rigid panel.

What material is PUF?

Polyurethane foam is a type of insulation that is made from a chemical reaction between two types of molecules. One of the molecules is a hydrocarbon, and the other is a dihydrocarboxylic acid.

What are the sizes of puf panels? What is the size of puf sheet?

Typical Width of PUF roof panels is 3.5’. Wall panels are 4’wide. Length of panels can be anything from 5’ to 40’. Though due to transportation limitation, panels are supplied in maximum length of 24’.

What are the properties of puf insulation? What are the properties of puf sheet?

- 1. Low Thermal Conductivity: PUF insulation has a low thermal conductivity, which means it is able to reduce the amount of heat that is transferred from one side of the material to the other.

- 2. High Fire Resistance: PUF insulation is highly fire resistant, making it a great choice for areas that require extra protection from fire.

- 3. Low Water Absorption: PUF insulation is able to resist water absorption, meaning it won’t absorb moisture and become damaged over time.

- 4. Low Compressibility: PUF insulation has a low compressibility, meaning it won’t be easily compressed or damaged by pressure.

- 5. High Durability: PUF insulation is highly durable and can withstand extreme temperatures, making it a great choice for long-term use.

- 6. Low Cost: PUF insulation is relatively inexpensive compared to other types of insulation, making it a great choice for those looking to save money.

What is the density of puf insulation? What is the density of PU sandwich panel?

The density of PUF insulation varies depending on the type and manufacturer, but generally ranges from 2.2 to 3.2 lbs/ft3 (35 to 51 kg/m3).

What is the advantage of using puf panels? What is the advantage of sandwich panel?

Advantages of PUF panel

- 1. Excellent Insulation: Due to its cellular structure, PUF panels provide excellent insulation. They can help keep homes cooler in the summer and warmer in the winter, reducing energy costs.

- 2. Exceptional Strength and Durability: Puf panels are extremely durable, lightweight and resistant to fire, chemicals and moisture. They are also impervious to damage from rodents, insects and birds, making them a great solution for areas prone to these conditions.

- 3. Integrative Design: The panels are designed to fit together in various shapes and configurations, allowing for both aesthetic appeal and a great degree of customization and flexibility.

- 4. Safe and Eco-friendly: PUF panels are chemically inert and contain no toxins, making them safe to use indoors, even around children and pets. In addition, they are 100% recyclable and biodegradable.

- 5. Quick Installation: PUF panels can be cut to size and installed quickly. This makes them particularly useful when remodeling or building a new structure.

- 6. Saving in Structural cost:- PUF panels from good brands like PRONTO are very strong over long spans. This eliminates the need of Purlins to a great extent. Thus reducing the overall cost of construction.

- 7. Soundproof: PUF panels are ideal for noise proofing. They not only provide insulation from heat, but also provide good sound proofing from both external and internal sources. This can make a home much more comfortable and peaceful.

- 8. Versatile: PUF panels can be used in almost any application, from walls to roofs, partitions, refrigeration enclosures, doors and windows, etc. They can also be used in many industries such as automotive, pharmaceutical, and aerospace.

- 9. Hygienic: PUF panels are a hygienic choice because they are easily cleaned and do not absorb moisture. Furthermore, they are flame retardant and can safely withstand high temperatures.

- 10. Low Weight: PUF panels are much lighter than traditional RCC construction, making them suitable for installation on existing buildings without needing additional reinforcements.

- 11. Modular: PUF panels are easily removable and re-assemblable, allowing for quick and cost-effective relocation if desired.

- 12. Reduced Structural Costs: PUF panels from reliable brands like Pronto can be used for long-span structures, eliminating the need for additional purlins and thus reducing construction costs.

- 13. Leak-Proof: Thick interlocking joints on PUF panels eliminate the risk of roof leakage, making them a great choice for areas with heavy rain or snow.

- 14. Long-Lasting: PUF panels are extremely durable, thanks to their good resistance to weathering and corrosion. When properly maintained, they can last up to 40 years.

- 15. Unbreakable: Thick, metal-faced PUF panels are highly resistant to impact, meaning they are less likely to be damaged compared to traditional cement roofing sheets.

What is the full form of puf sheet?

PUF is abbreviation for PolyUrethane Foam. A sheet made from PolyUrethane Foam is called PuF sheet.

What is the full form of puf panel?

PUF is abbreviation for Poly Urethane Foam. A panel made from PolyUrethane Foam is called puf panel.

Does PUF absorb water?

No, closed cell PUF (polyurethane foam) does not absorb water. It is a closed cell foam, meaning that the cells are sealed off from each other, preventing water from entering the foam.

Is PUF toxic?

No, PUF (polyurethane foam) is not toxic. PUF is a type of foam insulation that is made from a combination of polyols and isocyanates. It is non-toxic and non-allergenic, making it safe for use in homes and other buildings.

What temp does polyurethane melt? Does polyurethane melt with heat?

Polyurethane does not melt, but it can degrade at temperatures above 300°F (149°C).

What are the dangers of polyurethane?

Polyurethane is generally safe and not associated with any dangers when used for suitable applications. However, it should be noted that polyurethane can degrade at temperatures above 300°F (149°C) and can decay if kept submerged in water for a prolonged period of time.

What is the minimum slope for puf panel?

The minimum slope recommended for a PUF panel is 2 inches per foot (2:12). However, the slope may vary depending on the application and location. For example, in cold storage chambers, the roof slope is kept at zero, while in exposed buildings the typical slope is 2:12. Areas that experience heavy rains or snow may require a steeper slope for optimal protection.

What is the unit weight of puf panels?

As a general rule of thumb, a 50mm panel with metal facing weighs approximately 1kg/sqft. however this may vary depending on the panel’s thickness, facing material, and facing thickness.

What is PUF in HVAC?

PUF stands for Polyurethane Foam. It is a type of insulation used in HVAC systems to help reduce heat loss in ducts and other components, as well as to reduce sound transmission. PUF is often used in combination with other insulation materials, such as fiberglass and cellulose, to create a more efficient, effective insulation system.

What is PUF slab?

PUF slab is an insulation material made from polyurethane foam, commonly used for roofing, flooring, and as an insulator in walls, ceilings, and other areas. Its lightweight and durable properties, as well as its energy-efficiency, make it a popular choice for insulation needs. These slabs can be cut into sheets in desired thicknesses depending on the application, though this requires great skill and suitable tools.

Which panel is best for wall?

Pronto ready-to-install panels are an ideal choice for walls and industrial partitions, featuring a unique combination of strength and style. The newest addition to the Pronto range is wooden colour panels, which offer the strength of steel with the attractive appearance of wood.

What is PUF coating?

PUF coating is a type of protective coating that is used to provide a waterproof, fireproof, and vapor-proof barrier. It is typically used on roofs and other surfaces to protect them from the elements. PUF stands for Polyurethane Foam, which is a type of foam that is used as the base material of the coating. The PUF coating is applied in liquid form and quickly cures to form a hard and durable finish.

Which mm sheet is best for roofing?

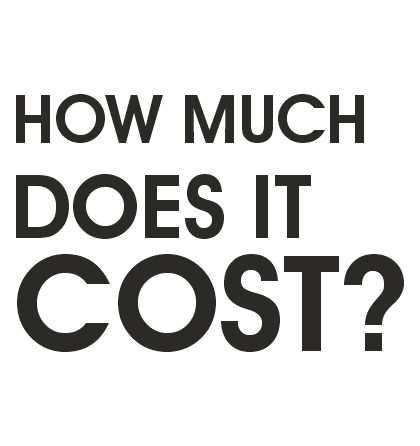

For roofing, the best mm sheet depends on the material used. Tin sheet is best between 0.40 to 0.50 mm, corrugated Cement sheet is best between 6-10 mm, and Pronto Insulated roof sheets is best between 30mm to 50mm (excluding crown).

Which is best sheet for roofing?

The best sheet for roofing is Pronto Insulated panels as they are heat proof and do not suffer from the disadvantages of corrugated tin sheet and cement sheets. Pronto panels are light weight and do not leak, and they have a longer life span than tin sheets. They also don’t heat up too much and are resistant to leakages that can occur with cement sheets.

What is the size of a wall panel?

Pronto wall panels are available in width of 4 feet and custom length upto 40 feet. Pronto has now introduced wooden texture finishes.