Are you constructing a modern, long-lasting, and energy-saving cold storage, mushroom grow chamber? Look no further than Pronto’s cutting-edge Cold Storage Puf Panels. Designed with the latest technology and materials, these panels are revolutionizing the way cold storage facilities are constructed.

Everything about Cold Storage Puf Panel

Construct Modern, Long life, Energy Saving Cold Storage with

Pronto's Cutting-Edge Cold Storage Puf Panels

Not just any PuF panel :

Large Infra must be built with top quality product

With their proprietary technology Pronto delivers product with exceptional durability, long life and high thermal resistance. Not only do these Puf Panels offer superior thermal efficiency, but they are also incredibly durable, making them a cost-effective choice for any cold storage project. What sets Pronto’s panels apart is their energy efficiency, weather resistance properties. By reducing heat transfer and minimizing temperature fluctuations, these panels help to significantly lower energy consumption, resulting in substantial cost savings over time. Say goodbye to outdated and inefficient local PU/PIR panels, and embrace the future of cold storage construction with Pronto’s cutting-edge Cold Storage Puf Panels.

Pronto’s Lowest Price Assurance: Last but not the least, with our large manufacturing facility and economies of scale, we are able to deliver panels at Mind Boggling Prices.

Key Features of Pronto's Cold Storage Puf Panels

Pronto’s Cold Storage Puf Panels are engineered with advanced technology and high-quality materials. Here are the key features that set them apart:

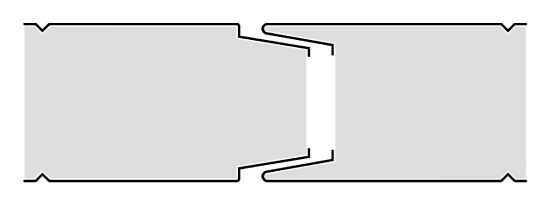

Pronto Tongue & Groove Joints for Perfect Joint: Way to High Thermal Efficiency

Pronto is a revolutionary product that offers superior thermal insulation, zero thermal bridging and structural stability. The joints between panels are critical for maintaining the integrity and efficiency of a cold storage facility. Pronto’s Cold Storage Puf Panels feature Tongue & Groove Joints that provide a perfect fit and seal between panels. This design not only enhances the structural stability but also contributes to high thermal efficiency by minimizing air leakage and heat transfer. Our innovative tongue and groove joints ensure the interlocking between the panels and press fit them together securely. The panels are designed in such a way that no thermal bridges are formed, with only quantum core foam coming in contact at the core.

Tounge and Groove Joints:-

New:-

Pronto Zero Contact Corner Pillars: Eliminate Thermal Bridging

Thermal bridging occurs when there is a break in the insulation, allowing heat to transfer through the structure. Pronto’s Cold Storage Puf Panels tackle this issue with their innovative Zero Contact Corner Pillars. These pillars ensure that there is no direct contact between the inner and outer metal sheets, eliminating thermal bridging and maintaining the desired temperature inside the cold storage facility. Pronto’s L corner pillars completely eliminate any possibility of thermal bridging, allowing for a sealed chamber at the corners without the need for flashings. Corners fittings and flashings creates a huge possibility of thermal bridging in cold storage. Pronto has totally eliminated this possibility by removing the need for flashing altogether.

Weather Protect Technology: High-Quality Paint and Galvalume Base Coat, a Must for Ultra-long Life

Cold storage and Mushroom plants have constantly maintained moisture and temperature levels, creating huge long-term deterioration of internal walls. This necessitates high quality of paint films and coatings. Pronto’s Cold Storage Puf Panels are built to withstand extreme weather conditions and ensure long-term durability. The panels are treated with Weather Protect Technology, which includes a high-quality paint finish and a galvalume base coat. This protective coating shields the panels from corrosion, UV rays, and other environmental factors, ensuring their longevity and minimizing maintenance requirements.

With these key features, Pronto’s Cold Storage Puf Panels offer unmatched performance, durability, and efficiency for modern cold storage facilities.

Thickness Available:-

Pronto is available in thicknesses of 30, 40, 50, 65, 80, and 105 mm.

These case studies demonstrate how Pronto’s Cold Storage Puf Panels have transformed cold storage facilities, addressing challenges, and delivering tangible benefits. By choosing Pronto’s panels, you can join the ranks of these successful businesses and revolutionize your cold storage operations.

APPLICATONS of Pronto Cold Storage PuF Panels

Puf Panels in Cold Rooms: Applications and Benefits

Cold rooms are essential for storing perishable goods at low temperatures. They are commonly used in industries such as food processing, pharmaceuticals, and horticulture. Puf panels play a crucial role in maintaining the desired temperature inside these cold rooms.

The exceptional insulation properties of Puf panels help minimize heat transfer, ensuring that the temperature inside the cold room remains constant. This not only helps preserve the quality and freshness of the stored goods but also reduces energy consumption.

Moreover, Puf panels offer excellent structural strength while being lightweight. This makes them easy to install and ensures that the cold room can be constructed without any structural support. Additionally, the panels have a top paint quality and hygienic surface that is easy to clean and maintain, contributing to a more sanitary environment and ultra long life.

Cold Rooms Panels

- • Medicine Storage Room

- • Ice Cream Storage Room

- • Frozen Food Storage Room

- • Vegetable Cold Room

- • Modular Cold Room

- • Commercial Cold Storage Room Panels

- • Fish Cold Room

- • Potato Cold Storage Room

- • Cold Storage Room

- • Milk Cold Storage Room

- • Mini Storage Cold Room

- • Meat Cold Room

- • Commercial Cold Room

- • Prefabricated Cold Rooms

- • Vegetable Cold Rooms

- • Sea Food Cold Storage Room

- • Flower Cold Room

- • Seeds Cold Storage Room

Puf Panels in Industrial Freezers & Cold Storage:

Applications and Benefits

Industrial freezers are used in various industries, including food processing, pharmaceuticals, and chemical storage. These freezers require efficient insulation to maintain low temperatures and prevent heat transfer from the external environment.

Puf panels are an ideal choice for industrial freezers due to their exceptional thermal insulation properties. They help minimize heat gain, ensuring that the desired temperature is maintained consistently. This is crucial for preserving the quality and safety of the stored products.

Additionally, with proprietary Quantum Core, Pronto Puf panels offer excellent dimensional stability, even at extremely low temperatures. This ensures that the panels maintain their structural integrity and insulation efficiency over time. The panels are also resistant to moisture, preventing the formation of ice and frost inside the freezer.

Cold Storage Panels

- • Commercial Cold Storage

- • Chemical Storage Cold Room

- • Controlled Atmosphere Cold Storage

- • Food Cold Storage Room

- • Multi Commodity Cold Storage

- • Ice Cream Storage Room

Puf Panels in Insulated Containers: Applications and Benefits

Insulated containers, also known as refrigerated containers or reefers, are used for transporting temperature-sensitive goods over long distances. These containers must maintain a controlled environment to ensure the integrity and freshness of the cargo.

Puf panels are widely used in insulated containers due to their lightweight and excellent insulation properties. The panels help create a barrier against external heat transfer, allowing the container to maintain the desired temperature throughout the journey.

Furthermore, Puf panels used in insulated containers are highly durable and resistant to mechanical stress. This ensures that the container can withstand the rigors of transportation without compromising insulation performance. The panels are also easy to clean and maintain, making them suitable for repeated use.

PUF panel for Ripening chambers:-

PUF panels are ideal for use in ripening chambers, which need to be able to maintain a consistent temperature and humidity level.

The benefits of using PUF panels in ripening chambers include:

- Improved temperature control: PUF panels are very effective at preventing heat loss, which helps to maintain a consistent temperature in the ripening chamber. This is important for ensuring that the fruits or vegetables ripen evenly.

- Reduced energy costs: PUF panels can help to reduce energy costs by preventing heat loss. This is because the chambers do not need to be heated as often or as much.

- Improved humidity control: PUF panels can also help to control humidity levels in the ripening chamber. This is important for ensuring that the fruits or vegetables do not dry out or become too moist.

- Longer shelf life: PUF panels can help to extend the shelf life of fruits and vegetables. This is because they help to prevent the fruits or vegetables from spoiling prematurely.

Ripening Chambers Panels

- • Ethylene Ripening Chamber

- • Banana Ripening Chamber

- • Fruits Ripening Chamber

- • Cold Storage Ripening Chamber

- • Controlled Atmosphere Ripening Chambers

- • Green Banana Ripening Chamber

PuF panels for Mushroom Growing Chambers:

A mushroom growing chamber is a controlled environment in which mushrooms are grown. It is a closed space that is designed to provide the ideal conditions for mushroom growth, including temperature, humidity, light, and ventilation. Mushrooms are a type of fungus that grows in a variety of environments, but they typically prefer cool, dark, and humid conditions. Mushroom growing chambers can be used to create these ideal conditions, regardless of the climate outside.

There are many different types of mushroom growing chambers, but they all share some common features. They typically have a well-insulated structure to help maintain the desired temperature and humidity levels. They also have a ventilation system to provide fresh air and to remove stale air. Some mushroom growing chambers are very simple, while others are more complex. Some are designed for commercial mushroom production, while others are designed for home use.

The benefits of using a mushroom growing chamber constructed with Pronto Puf panel include:

- Controlled environment: The environment in a mushroom growing chamber can be controlled, which helps to ensure that the mushrooms grow evenly and that they are of high quality.

- Increased yields: Mushroom growing chambers can help to increase yields of mushrooms. This is because the conditions in the chamber are ideal for mushroom growth, and there is less risk of pests or diseases.

- Reduced costs: Mushroom growing chambers can help to reduce costs. This is because the conditions in the chamber can be controlled, which reduces the amount of energy that is needed to grow mushrooms.

Mushroom Grow Chamber Panels

- · Mushroom growing room

- · Mushroom plant

- · Mushroom growing chamber

How Pronto's Cold Storage Puf Panels are Different from Traditional Cold Storage Solutions

Traditional cold storage construction methods often involve multiple layers of insulation, concrete walls, and complex installation processes. In contrast, Pronto’s Cold Storage Puf Panels provide a simplified and efficient solution. Here’s how they differ from traditional cold storage solutions

Superior Insulation

Pronto’s Quantum Core delivers exceptional insulation properties, ensuring maximum thermal efficiency. Their high-density polyurethane foam core and advanced manufacturing techniques provide superior insulation compared ordinary PU/PIR panels. Energy consumption is a major concern in cold storage facilities. Traditional construction methods like brick and cement always result in significant heat loss and energy wastage.

Faster Installation

Constructing a traditional cold storage facility can be time-consuming and labor-intensive. Pronto’s Cold Storage Puf Panels are designed for quick and easy installation. The panels come in pre-fabricated sizes and can be easily assembled, significantly reducing construction time and costs.

Flexibility and Customization

Traditional cold storage construction often limits the flexibility to expand or modify the facility in the future. Pronto’s Cold Storage Puf Panels offer greater flexibility and customization options. These panels can be easily reconfigured or expanded as per the changing needs of your business, without the need for extensive renovations or disruptions. Special thickness panels like 65mm and 105mm are especially made to give that extra edge to your cold storage and mushroom plants.

Affordable Price

Despite high quality standards and stringent quality control, Pronto is committed to deliver products at Lowest Price. Pronto’s large scale operations enable us to manufacture top quality at mind-boggling prices. So, why to settle with less quality when you get high quality trusted brand at Affordable Prices.

By embracing Pronto’s cutting-edge Cold Storage Puf Panels, you can overcome the limitations of traditional cold storage solutions and enjoy the benefits of a modern, energy-efficient, and cost-effective facility.

The Importance of Energy Efficiency in Cold Storage Facilities

Energy efficiency is a critical factor in cold storage facilities. The high energy demands of refrigeration and maintaining optimal temperatures can result in significant costs and environmental impact. Here’s why energy efficiency should be a top priority when constructing a cold storage facility

Cost Savings

Energy costs can constitute a significant portion of the operational expenses in a cold storage facility. By investing in energy-efficient solutions like Pronto’s Cold Storage Puf Panels, you can reduce energy consumption, resulting in substantial cost savings over time. These savings can be allocated to other business priorities or reinvested in further improvements.

Environmental Impact

Cold storage facilities contribute to carbon emissions due to their energy-intensive operations. By adopting energy-efficient practices and using technologies like Pronto’s Cold Storage Puf Panels, you can minimize your facility’s environmental footprint. Reducing energy consumption not only helps combat climate change but also positions your business as environmentally responsible and sustainable.

Regulatory Compliance

Governments and regulatory bodies are increasingly enforcing stricter energy efficiency standards. Constructing an energy-efficient cold storage facility ensures compliance with regulations and avoids potential penalties or restrictions.

Operational Reliability

Energy efficiency is closely linked to the reliable operation of cold storage facilities. By minimizing temperature fluctuations and heat transfer, energy-efficient solutions like Pronto’s Cold Storage Puf Panels help maintain a consistent and optimal storage environment. This reliability is crucial for preserving the quality and safety of perishable goods.

By prioritizing energy efficiency in cold storage facilities, businesses can achieve significant cost savings, reduce their environmental impact, comply with regulations, and ensure reliable operations.

Case Studies Showcasing some unique implementation of

Pronto Cold Storage Panels:

Pronto’s Cold Storage Puf Panels have been successfully implemented in various cold storage projects, delivering exceptional results.

Here are some case studies that highlight their effectiveness:

1. Chocolate Distributor

A leading Chocolate distributor company, faced challenges with their storage facility. The warehouse was in basement of existing RCC building. Air conditioning was not at all effective and there were huge electricity bills. The facility suffered from high energy consumption and inconsistent temperature control, resulting in product spoilage. They made all internal partitions with Pronto Panels and cladded existing wall with Pronto panels. By using Pronto’s Cold Storage Puf Panels, client achieved a significant reduction in energy consumption and improved temperature stability. This not only reduced operational costs but also enhanced the quality and shelf life of their products. The cost of Pronto panels was similar to the cost of Aluminum partitions work, which was a huge price savings. Additionally, these panels can be reused and shifted whenever client wish to shift their rented premises.

2. Mushroom Plant at Sahapura:

Triveni Protein constructed a greenfield mushroom growing facility near Sahapura, Jaipur. As mushroom facility have high interior moisture levels, client was concerned with durability of paint films and coatings, as long term contact with moisture may degrade walls of facility. Pronto’s Cold Storage Puf Panels provided panels with Edge Protect and Weather-shield technology that are highly durable and can withstand moisture impact. Client also experienced substantial energy savings and low budget construction saved a ton of money in their project cost.

These case studies demonstrate how Pronto’s Cold Storage Puf Panels have transformed cold storage facilities, addressing challenges, and delivering tangible benefits. By choosing Pronto’s panels, you can join the ranks of these successful businesses and revolutionize your cold storage operations.

Steps to Construct a Modern, Long-life, Energy-saving Cold Storage Using Pronto's Panels

Constructing a modern, long-life, and energy-saving cold storage facility using Pronto’s Cold Storage Puf Panels involves several essential steps. Here’s a general overview of the construction process

Design and Planning

Work with a professional design team to create a customized cold storage facility layout that meets your specific requirements. Consider factors such as storage capacity, temperature zones, accessibility, and future expansion.

Site Preparation

Prepare the construction site by clearing the area and ensuring a level foundation. Address any soil or drainage issues that may affect the stability and longevity of the facility.

Doors and Access Points

Install high-quality cold storage doors and access points that provide proper insulation and are easy to operate. Consider features like air curtains or strip curtains to minimize air leakage during door openings.

HVAC and Refrigeration Systems

Install an efficient HVAC and refrigeration system that is properly sized for your facility’s requirements. Ensure that the system integrates seamlessly with the cold storage panels and provides optimal temperature control and energy efficiency.

Panel Installation

Begin by installing the base panels, ensuring proper alignment and sealing. Assemble the remaining panels, ensuring a tight fit and secure joints. Follow the manufacturer’s instructions and guidelines for panel installation and use appropriate tools and equipment.

Roof and Flooring

Install the roof panels, ensuring proper insulation and sealing. Consider additional insulation measures, such as reflective coatings or insulation blankets, to enhance energy efficiency. Install the flooring system, ensuring it is suitable for cold storage operations and provides adequate insulation and durability.

Finishing and Testing

Apply the final finishes, such as paint or protective coatings, to the panels and facility surfaces. Perform thorough testing of the facility, including temperature control, insulation performance, and energy consumption monitoring. Make any necessary adjustments or improvements to ensure optimal functionality.

By prioritizing energy efficiency in cold storage facilities, businesses can achieve significant cost savings, reduce their environmental impact, comply with regulations, and ensure reliable operations.

The Pronto Trust

With numerous years of experience,

Pronto is a name behind thousand of projects

including restaurents, schools, farm houses, factories,

warehouse, hospitals and more.

Pronto panels are known for their strength,

insulation and long life.